Haɗin DRV Na Akwatunan Gear tsutsa Biyu

Bayani dalla-dalla

Masu rage haɗin haɗin gwiwarmu suna samuwa a cikin zaɓuɓɓukan wutar lantarki iri-iri, daga 0.06 zuwa 1.5kW. Tare da irin wannan kewayon iko mai faɗi, abokan ciniki za su iya zaɓar samfurin da ya fi dacewa da takamaiman aikace-aikacen su. Bugu da ƙari, waɗannan masu ragewa suna ba da matsakaicin ƙarfin fitarwa na 3000Nm, suna tabbatar da cewa za su iya gudanar da ayyukan masana'antu masu buƙata.

Ayyuka mara misaltuwa

Ɗayan babban fa'idar akwatunan kayan haɗin gwiwar mu na yau da kullun shine ƙwararren aikinsu. Ta hanyar haɗuwa da DRVs na zamani, abokan ciniki suna da sassaucin ra'ayi don zaɓar rabon da ya fi dacewa da bukatun su, daga 100 zuwa 5000. Wannan yana tabbatar da daidaitattun daidaito da inganci a watsa wutar lantarki.

An tabbatar da abin dogaro

Mun san cewa idan ana batun injinan masana'antu, dogaro yana da mahimmanci. Shi ya sa a hankali muke ƙirƙira masu rage haɗin haɗin gwiwarmu ta amfani da mafi ingancin kayan don tabbatar da dorewarsu da dorewa.

Akwatin mai rage mu an yi shi da babban tushe na gami da aluminum gami da 025-090, wanda yake da tsatsa-hujja da juriya. Don sansanonin 110-150 muna amfani da simintin ƙarfe, wanda ya shahara saboda amincinsa da dorewa. Wannan yana tabbatar da masu rage mu zasu iya jure yanayin aiki mafi tsauri, yana bawa abokan cinikinmu kwanciyar hankali.

Bugu da ƙari, muna alfahari da kayan da ake amfani da su don dawo da sassa. An yi tsutsa da kayan gami mai inganci kuma ana yin maganin taurin ƙasa don inganta ƙarfinta da rayuwar sabis. Taurin saman haƙori na mai rage mu shine 56-62HRC, wanda ke ba da kyakkyawan aiki da juriya.

Bugu da kari, kayan tsutsa an yi su ne da tagulla mai inganci, mai jure lalacewa, wanda ke kara inganta aminci da karko na masu rage mu. Wannan yana tabbatar da santsi da ingantaccen watsa wutar lantarki yayin rage haɗarin lalacewa.

a karshe

Masu rage haɗin haɗin gwiwar mu suna ba da haɗin kai mara misaltuwa, aiki da aminci. Tare da kewayon ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa kamar saurin canzawa, babban fitarwa mai ƙarfi da gini mai ɗorewa, masu rage mu sune cikakkiyar mafita don aikace-aikacen masana'antu iri-iri.

Saka hannun jari a cikin masu rage haɗin haɗin gwiwarmu kuma ku sami ƙarfin ƙirƙira da keɓancewa. Amince sadaukar da mu ga inganci da aminci. Tuntuɓe mu a yau don ƙarin koyo game da yadda masu rage mu zasu iya canza injin ɗin masana'antar ku.

Aikace-aikace

Screw feeders don kayan haske, magoya baya, layin taro, bel ɗin jigilar kayan haske, ƙananan mahaɗa, ɗagawa, injin tsaftacewa, masu cikawa, injin sarrafawa.

Na'urorin iska, masu ciyar da na'ura na itace, kayan ɗagawa, ma'auni, injin zare, matsakaitan mahaɗa, bel ɗin jigilar kayayyaki don nauyi, winches, ƙofofin zamiya, taki scrapers, injunan tattara kaya, masu haɗawa da kankare, injin crane, injin niƙa, injin nadawa, famfo gear.

Masu hadawa don abubuwa masu nauyi, shears, presses, centrifuges, goyan baya masu juyawa, winches da ɗagawa don kaya masu nauyi, niƙa lathes, injin niƙa, bucket lif, injin hakowa, injin guduma, injina na cam, injin nadawa, turntables, tumbling ganga, vibrators, shredders .

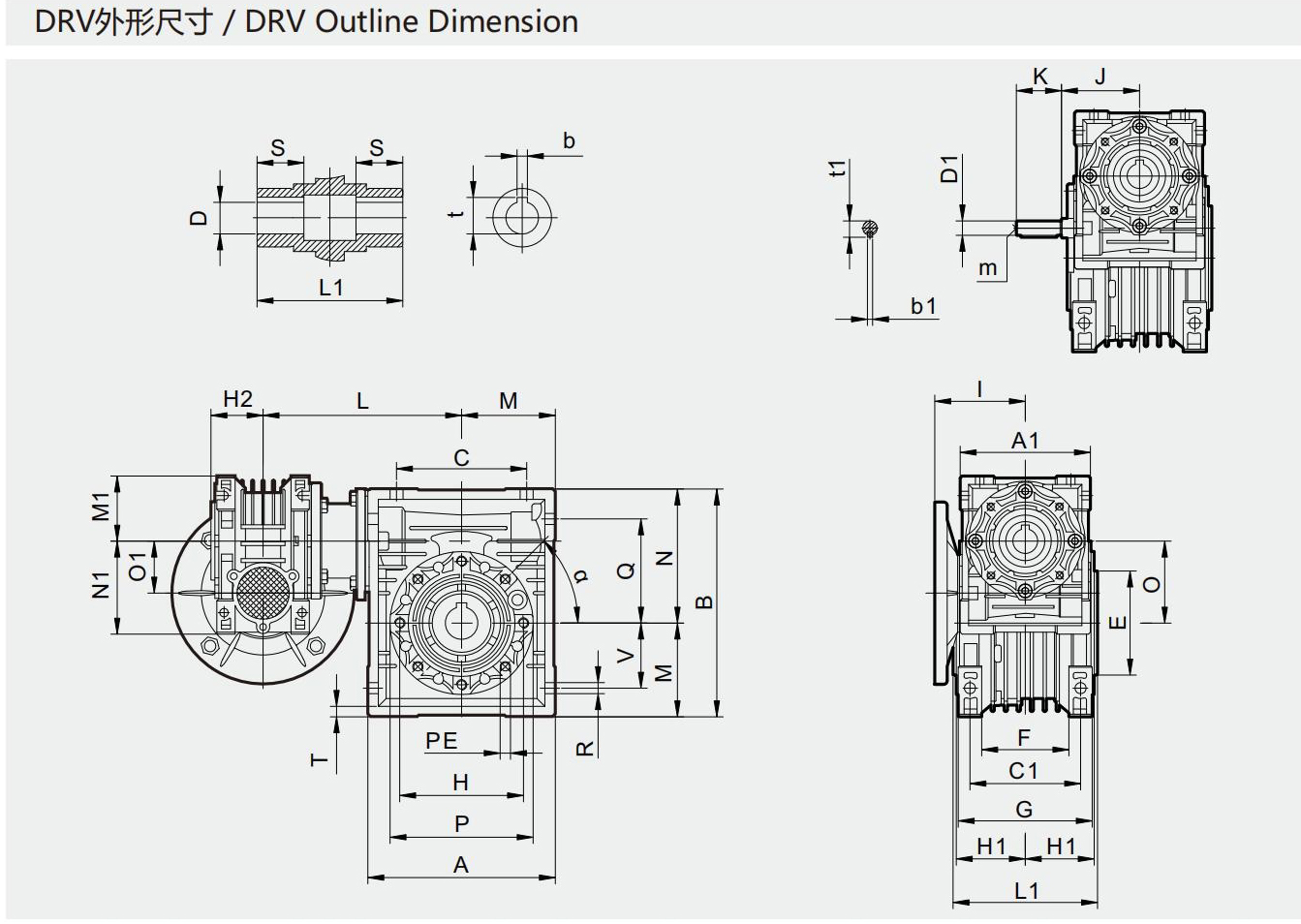

| DRV | A | A1 | B | C | C1 | D (H8) | D1(j6) | E (h8) | F | G | H | H1 | H2 | I | J | K | L | L1 | M | M1 |

| 025/030 | 80 | 70 | 97 | 54 | 44 | 14 | - | 55 | 32 | 56 | 65 | 29 | 22.5 | 45 | - | - | 100 | 63 | 40 | 35 |

| 025/040 | 100 | 70 | 121.5 | 70 | 60 | 18 (19) | - | 60 | 43 | 71 | 75 | 36.5 | 22.5 | 45 | - | - | 115 | 78 | 50 | 35 |

| 030/040 | 100 | 80 | 121.5 | 70 | 60 | 18 (19) | 9 | 60 | 43 | 71 | 75 | 36.5 | 29 | 55 | 51 | 20 | 120 | 78 | 50 | 40 |

| 030/050 | 120 | 80 | 144 | 80 | 70 | 25(24) | 9 | 70 | 49 | 85 | 85 | 43.5 | 29 | 55 | 51 | 20 | 130 | 92 | 60 | 40 |

| 030/063 | 144 | 80 | 174 | 100 | 85 | 25 (28) | 9 | 80 | 67 | 103 | 95 | 53 | 29 | 55 | 51 | 20 | 145 | 112 | 72 | 40 |

| 040/075 | 172 | 100 | 205 | 120 | 90 | 28 (35) | 11 | 95 | 72 | 112 | 115 | 57 | 36.5 | 70 | 60 | 23 | 165 | 120 | 86 | 50 |

| 040/090 | 206 | 100 | 238 | 140 | 00 | 35 (38) | 11 | 110 | 74 | 130 | 130 | 67 | 36.5 | 70 | 60 | 23 | 182 | 140 | 103 | 50 |

| 050/110 | 255 | 120 | 295 | 170 | 115 | 42 | 14 | 130 | - | 144 | 165 | 74 | 43.5 | 80 | 74 | 30 | 225 | 155 | 127.5 | 60 |

| 063/130 | 293 | 144 | 335 | 200 | 120 | 45 | 19 | 180 | - | 155 | 215 | 81 | 53 | 95 | 90 | 40 | 245 | 170 | 146.5 | 72 |

| 063/150 | 340 | 144 | 400 | 240 | 45 | 50 | 19 | 180 | - | 185 | 215 | 96 | 53 | 95 | 90 | 40 | 275 | 200 | 170 | 72 |

| DRV | N | N1 | O | 01 | P | Q | R | S | T | V | PE | a | b | b1 | t | t1 | m | Kg |

| 025/030 | 57 | 48 | 30 | 25 | 75 | 44 | 6.5 | 21 | 5.5 | 27 | M6×10(n=4) | 0° | 5 | - | 16.3 | - | - | 1.9 |

| 025/040 | 71.5 | 48 | 40 | 25 | 87 | 55 | 6.5 | 26 | 6.5 | 35 | M6×10(n=4) | 45° | 6 | - | 20.8 (21.8) | - | - | 3 |

| 030/040 | 71.5 | 57 | 40 | 30 | 87 | 55 | 6.5 | 26 | 6.5 | 35 | M6×10(n=4) | 45° | 6(6) | 3 | 20.8 (21.8) | 10.2 | - | 3.65 |

| 030/050 | 84 | 57 | 50 | 30 | 100 | 64 | 8.5 | 30 | 40 | M8×10(n=4) | 45° | 8(8) | 3 | 28.3 (27.3) | 10.2 | - | 4.85 | |

| 030/063 | 102 | 57 | 63 | 30 | 110 | 80 | 8.5 | 36 | 8 | 50 | M8×14(n=8) | 45° | 8(8) | 3 | 28.3 (31.3) | 10.2 | - | 6.95 |

| 040/075 | 119 | 71.5 | 75 | 40 | 140 | 93 | 11 | 40 | 10 | 60 | M8×14(n=8) | 45° | 8 (10) | 4 | 31.3 (38.3) | 12.5 | - | 11.1 |

| 040/090 | 135 | 71.5 | 90 | 40 | 160 | 02 | 13 | 45 | 11 | 70 | M10×18(n=8) | 45° | 10 | 4 | 38.3 (41.3) | 12.5 | - | 14.3 |

| 050/110 | 167.5 | 84 | 110 | 50 | 200 | 125 | 14 | 50 | 14 | 85 | M10×18(n=8) | 45° | 12 | 5 | 45.3 | 16 | - | 46 |

| 063/130 | 187.5 | 102 | 13C | 63 | 250 | 140 | 16 | 60 | 15 | 100 | M12×21(n=8) | 45° | 14 | 6 | 48.8 | 21.5 | M6 | 59.6 |

| 063/150 | 230 | 102 | 150 | 63 | 250 | 180 | 18 | 72.5 | 18 | 120 | M12×21(n=8) | 45° | 14 | 6 | 53.8 | 21.5 | M6 | 96.7 |